Analyzing the Carbon Cost of Global Automotive Supply Chains: World 7.com, Mahadev book login id and password, Silver exchange demo id

world 7.com, mahadev book login id and password, silver exchange demo id: Analyzing the Carbon Cost of Global Automotive Supply Chains

When we think about the environmental impact of the automotive industry, our minds often go straight to emissions from vehicles on the road. However, a significant portion of a car’s carbon footprint actually comes from its supply chain. From sourcing raw materials to manufacturing components to transporting finished vehicles, the global automotive supply chain plays a crucial role in determining the overall carbon cost of the industry.

Understanding the carbon cost of automotive supply chains is essential for identifying areas where efficiency improvements can be made and emissions can be reduced. By analyzing the various stages of a car’s production process, we can pinpoint where the most significant environmental impacts lie and work towards finding sustainable solutions.

Raw Material Sourcing

The first step in the automotive supply chain is the sourcing of raw materials. Metals like steel and aluminum, as well as plastics and rubber, are essential components of vehicle manufacturing. The extraction and processing of these materials often involve energy-intensive processes that emit large amounts of carbon dioxide.

Component Manufacturing

Once the raw materials are sourced, they are then transformed into components like engines, body panels, and electronics. The manufacturing of these parts typically requires a significant amount of energy, leading to further carbon emissions.

Assembly and Production

The final stage of the supply chain involves assembling the various components into a finished vehicle. This process also contributes to the carbon cost of the automotive industry, as it requires energy for welding, painting, and other assembly tasks.

Transportation

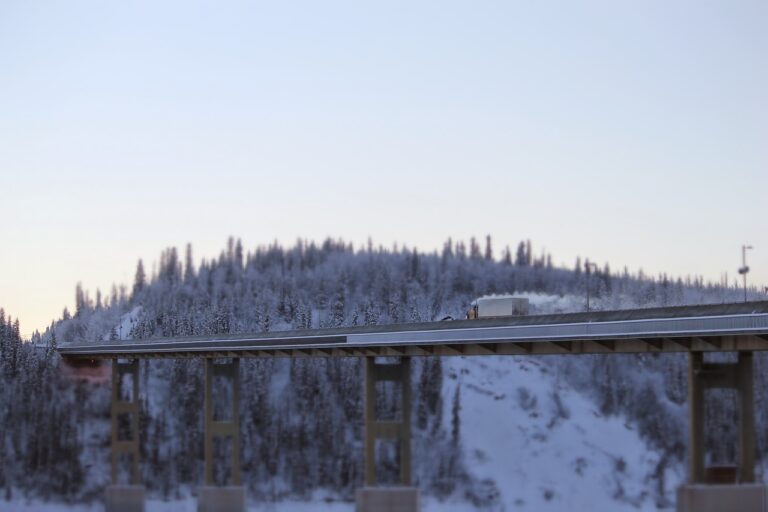

One of the most significant contributors to the carbon footprint of automotive supply chains is the transportation of parts and vehicles between various stages of production. Whether by truck, train, ship, or plane, the logistics of moving components around the globe result in substantial emissions.

Storage and Warehousing

Throughout the supply chain, components and vehicles may spend time in warehouses and storage facilities. These buildings often require heating, cooling, and lighting, all of which add to the overall carbon cost of the industry.

End-of-Life Recycling

Finally, the disposal and recycling of vehicles at the end of their life cycle also contribute to the carbon footprint of the automotive supply chain. Properly recycling materials can help reduce emissions and minimize the environmental impact of the industry.

FAQs

Q: How can automotive companies reduce the carbon cost of their supply chains?

A: By utilizing more sustainable materials, optimizing transportation routes, investing in renewable energy sources, and prioritizing recycling and waste reduction, companies can make significant strides in reducing their carbon footprint.

Q: Are there any regulations in place to limit the environmental impact of automotive supply chains?

A: Some regions have implemented regulations aimed at reducing emissions from vehicles, but there is still a long way to go in regulating the entire supply chain. Companies are increasingly recognizing the importance of sustainability and are taking steps to address their environmental impact voluntarily.

In conclusion, analyzing the carbon cost of global automotive supply chains is essential for understanding the environmental impact of the industry and finding ways to make it more sustainable. By focusing on each stage of the production process and implementing measures to reduce emissions, companies can work towards a greener future for the automotive sector.